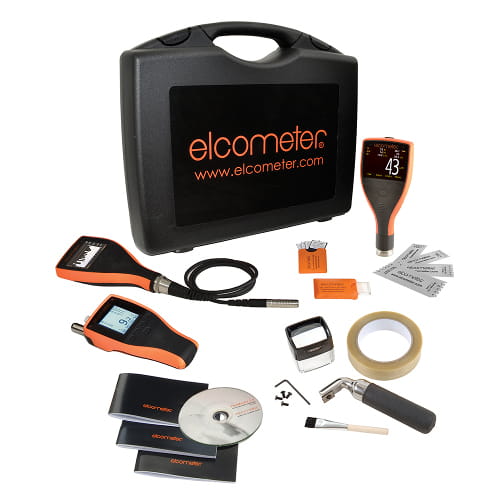

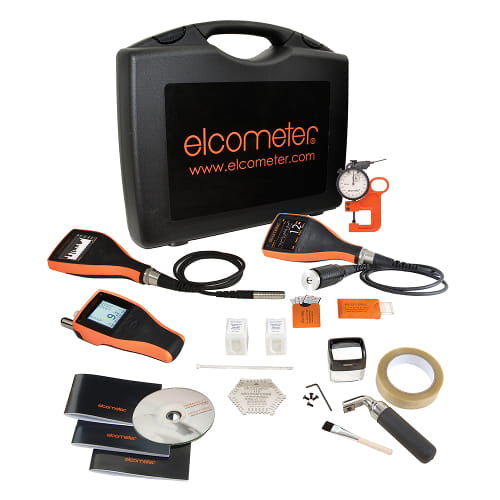

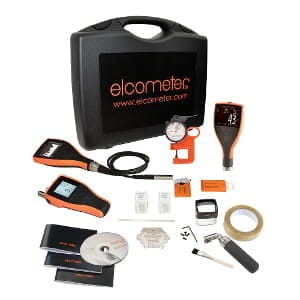

Inspection Kits for Coating & Surfaces

The inspection kits bring together all essential test instruments for

powder coating and wet paint in one compact,

mobile case. They contain equipment for coating thickness measurement,

climate and dew point determination, gloss and colour measurement,

adhesion testing, roughness evaluation,

surface cleanliness and salt contamination testing as well as porosity testing.

All components are standards-compliant, calibratable and designed

for mobile on-site use.

Applications & benefits

The kits are used in incoming goods inspection, production,

quality assurance and audits.

They support fast and reliable assessment of

coating quality and surface preparation.

By combining all relevant test methods – from the climate check (ΔT)

and coating thickness control through to adhesion testing –

they ensure a high first-pass yield, enable

complete traceability and significantly reduce rework

and inspection effort.

Measurement tasks & kit configuration

Coating thickness:

selecting a suitable gauge or sensor for FE and

NFE substrates as well as complex geometries.

Use of calibration foils and zero plates

for adjustment and to ensure accurate results even on different substrates.

Climate / dew point:

measuring air temperature, surface temperature

and relative humidity to determine ΔT

before coating.

The results form the basis for release according to climatic specifications

and help prevent condensation.

Gloss / colour:

carrying out measurements with 20° and 60° geometry and

evaluating the ΔE* value according to ISO/ASTM standards.

This ensures uniform colour and gloss appearance across batches.

Adhesion / roughness:

assessing adhesion using cross-cut or

pull-off tests and determining surface texture

with Rubert roughness standards.

The results provide insight into adhesion, surface preparation and coating quality.

Cleanliness / porosity:

checking surface cleanliness using the Bresle test,

dust level checks and porosity testing.

In addition, a light and visual inspection

makes it possible to assess the coating surface for defects and visual imperfections.

Product ranges & integration

The range includes standard and customised kits

with QA software, data loggers and

interfaces for digital inspection reports.

We define the scope of testing, applicable standards

and measurement point plan and integrate the kits fully into

QA workflows, report archives and

audit processes.

This ensures that all results are available in a standardised, traceable

and audit-ready form.

Key benefits at a glance

- Everything in one case – practical selection, ready to use

- Standards-compliant – ISO/ASTM, traceable calibration, certificates

- Digital documentation – data export, reports & traceability

- Less rework – consistent results, clear release criteria

Leading manufacturers – inspection kits

- Elcometer – kits for coating thickness, climate, cleanliness & roughness.

- DeFelsko – PosiTector/PosiTest kits incl. FE/NFE, climate & adhesion.

- BYK-Gardner – gloss/colour cases and appearance inspection.

- TQC Sheen – paint test cases, cross-cut, wet film thickness, roughness.

- Neurtek – complete sets for gloss, colour, adhesion & coating thickness.

- Mahr – roughness and contour measurement for QA cases.

- Rubert – reference plates & comparison standards for roughness.

- 3M – inspection accessories: abrasives/masking and cleaning products.

- KSJ – gloss meters and portable sets.

- Testo – climate/dew point measurement cases.

- Datapaq/Fluke – temperature/oven profile loggers (kit integration).

- PCE Instruments – handheld instruments & loggers for QA sets.

- Extech – electrical/environmental instrumentation for inspection cases.

- Rotronic – humidity/temperature for climate kits.

- OMEGA – sensors, probes & data acquisition.

- SATA – test and accessory components for coating.

- Phoenix Instrument – lab/test equipment for inspection sets.

- SIS Verlag – standards/guidelines & training materials in the kit.

- beschicht. – QA templates, calibration sets & customised kit configuration.

Go directly to inspection kits –

or to consulting & kit configuration.

Frequently asked questions about inspection kits

Which test instruments belong in an inspection kit for coatings?

Typically included are a coating thickness gauge (FE/NFE), climate and dew point measurement, gloss and, where required,

colour measurement, adhesion testing (cross-cut/pull-off), roughness comparison (Rubert),

surface cleanliness/salt contamination (e.g. Bresle), porosity testing as well as light/inspection lamp.

Calibration foils, zero plates and report templates complete the set.

How do I choose the right inspection kit?

Selection is based on substrate (FE/NFE), process step (incoming goods, production, audit), applicable standards

(e.g. ISO 2178/2360, ASTM D7091, ISO 2813, ISO 2409), required accuracy, documentation needs

(data loggers/interfaces) and operating environment. Traceable calibration and suitable accessories in the case are essential.

What improves traceability and audit readiness when using inspection kits?

A defined measurement point plan, calibrated test instruments with certificates, delta-T control before coating,

oven/temperature profiles according to coating specification, digital data acquisition and clear test reports.

Regular test equipment monitoring and user training ensure consistent results.