Surface cleanliness: the key to optimal coating quality

The purity of surfaces is a crucial factor in coating processes. Contaminants, especially soluble salts (chlorides, sulfates, nitrates), dust and dirt, can impair the adhesion of the coating and lead to premature failure. In particular, in industry – from automotive to aerospace – surface preparation must be strictly controlled to ensure long-term durability and corrosion resistance.

Why is surface cleanliness so important?

Contamination on surfaces can have serious consequences:

- Corrosion: soluble salt residues promote the formation of rust.

- Loss of adhesion: dust and dirt reduce the adhesion of the coating to the surface.

- Aesthetic defects: dirt particles under the coating lead to visible irregularities.

Measuring technology for surface cleanliness

To ensure surfaces are completely clean, we provide accurate surface contamination measurement solutions. These gauges detect the smallest contamination:

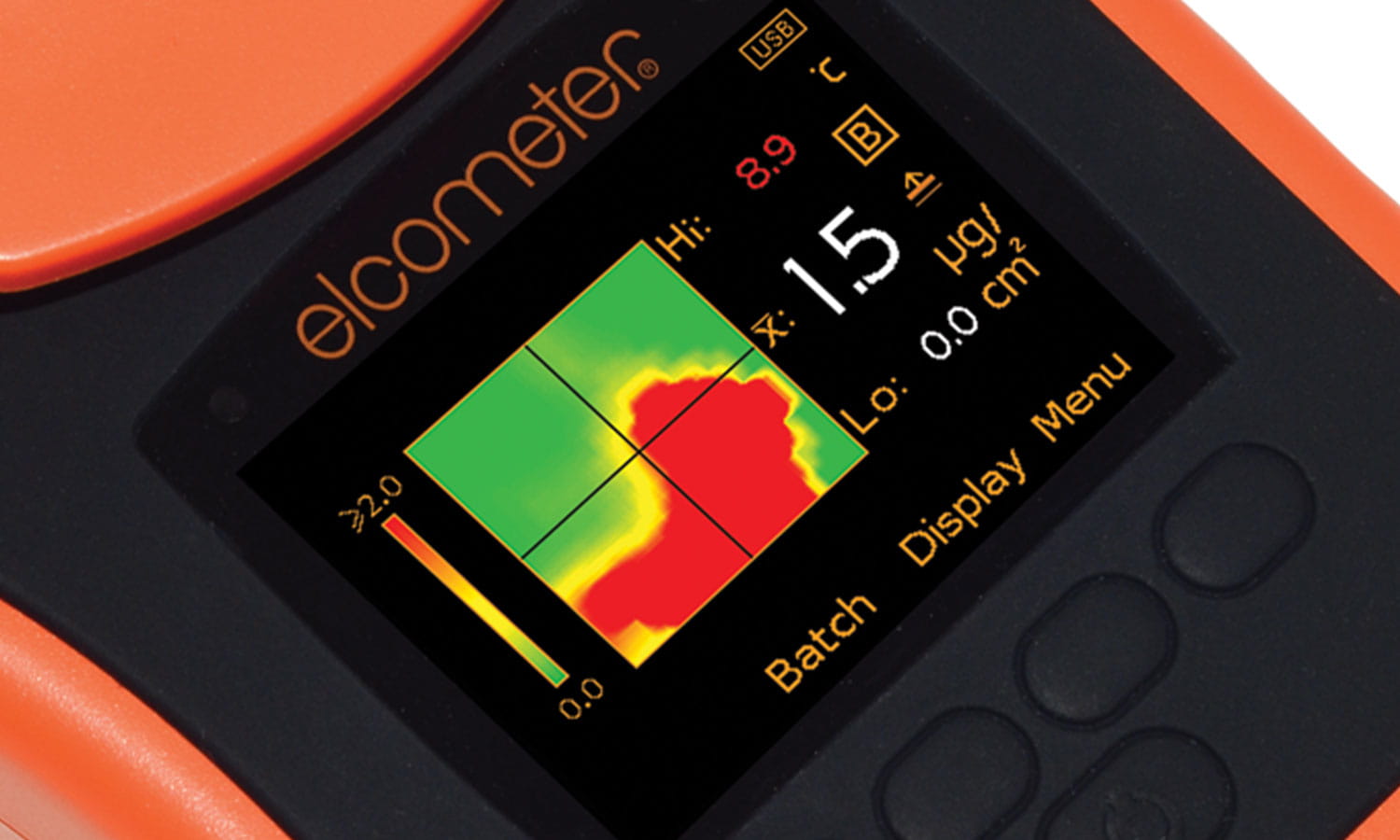

- Elcometer 130 Salt Contamination Meter: measures soluble salts which could cause corrosion.

- Elcometer 142 Dust Test Kit: provides a quick assessment of the amount of dust on surfaces prior to coating.

How these devices improve your coating processes

By using these measurement techniques, you guarantee optimal conditions for the coating process and significantly reduce the risk of coating defects. With our products, you can ensure that every coating is optimally applied and provides maximum protection.

Discover our solutions for surface cleanliness

With the right surface cleanliness equipment, you can ensure that your coatings meet the highest quality standards. Visit our shop and find the right tools to protect your projects from corrosion and contamination.

Order the best test equipment now and ensure that your surfaces are perfectly prepared!