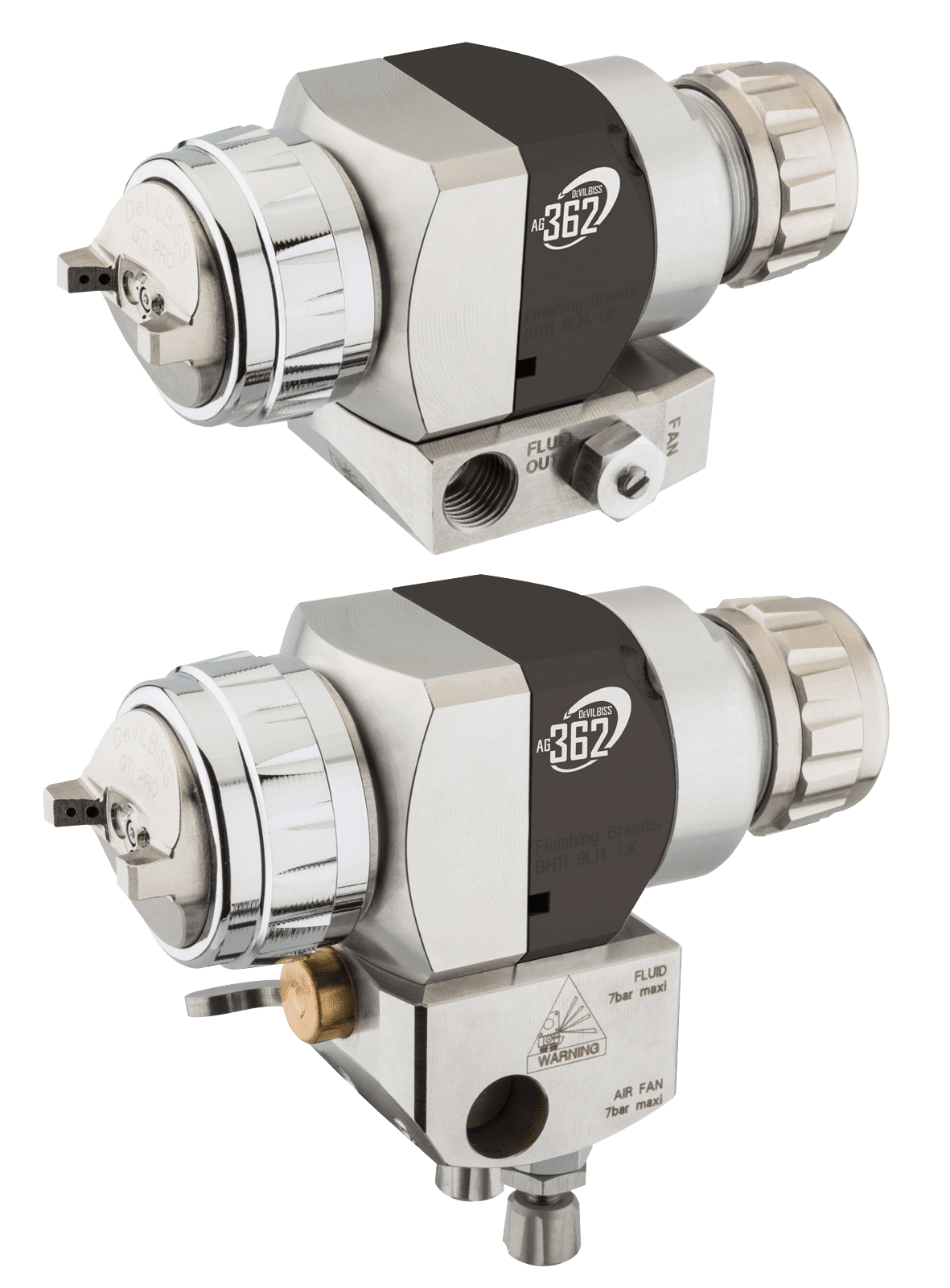

DeVilbiss AG362 automatic compressed air spray gun, 0.7 mm nozzle set, adapter, lever, micrometer

€1,356.60*

% €1,808.80* (25% saved)Prices include VAT plus shipping costs

Price excl. VAT

Fast Shipping

Scope of delivery

DeVilbiss AG362 – Automatic compressed air spray gun

The AG362 is a modular, automatically operated low-pressure spray gun for industrial coatings. It is available with either a quick-release lever manifold (AG-362L) or screw manifold (AG-362S), supports HVLP, Trans-Tech and conventional air caps and is suitable for solvent- and water-based materials. ATEX: II 2 G X T6 (Zone 1/2).

Sources: Functional description, specifications & ATEX (operating instructions).

Highlights & advantages

- Modular quick-change design: lever (fastest disassembly) or screw distributor (compact, versatile mounting). :contentReference[oaicite:3]{index=3}

- Wide range of air caps (conventional, Trans-Tech, HVLP) for efficiency and fine spray pattern.

- Independent FAN/ATOM/trigger air – important for robots and fully automatic machines. :contentReference[oaicite:5]{index=5}

- Quick-release manifolds for fast changeovers and minimal downtime. :contentReference[oaicite:6]{index=6}

- Industrial-grade materials and QuickClean™ surfaces for cleaning and durability. :contentReference[oaicite:8]{index=8}

- PG6/EPA-compliant HVLP/HE variants with > 65% transfer efficiency.

Areas of application

General industrial coating, top coating on machines & fixtures; integration into robotic/gantry/stationary systems. Suitable for solvent- and water-based media.

Technical data

| Feature | Value |

|---|---|

| ATEX | II 2 G X T6 (Zone 1/2) |

| Media | Solvent- and water-based materials |

| Air caps | Conventional, Trans-Tech, HVLP |

| P1/P2 (max.) | 7 bar air / 7 bar liquid |

| Cylinder air (operation) | 4–7 bar |

| Ambient | up to 40 °C (nominal) |

| Connections – lever manifold | CYL 1/8" G; ATOM/FAN each 1/8" G; Fluid IN/OUT 1/8" G |

| Connections – screw manifold | CYL 1/8" G; CAP (ATOM+FAN) 1/4" G; Fluid IN/OUT 1/4" NPS |

| Dimensions (gun only) | AG-362: 122 × 44 × 44 mm; weight approx. 557 g |

| Materials (typical) | According to DeVilbiss manual: Body chemically nickel-plated brass; head/lines QuickClean™ aluminium; air cap stainless steel; tip/needle stainless steel (optionally nitride-coated). According to Binks data sheet: Gun head & fluid passageways stainless steel; body QuickClean™ aluminium; manifold stainless steel; nozzle/needle etc. 303 SS/nitride/tungsten carbide; seals HDPE/FEPM/PTFE/FFKM. |

Sources: Specifications & connections (operating instructions p. 2); connection/weight/material specifications & performance data (Binks AG-360 Series, specification table). :contentReference[oaicite:13]{index=13}

Versions & part numbers

The AG-362 numbering codes the air cap type (C/HV/TE), nozzle size (e.g. 0.85/1.0/…/2.8 mm) and rear option (e.g. F = full needle travel, M = micrometer). Air cap kits include: PRO-100-TE10/20/30/40/50-K, PRO-100-HV30-K; Conventional PROC-120-C1/C2/C3-K.

Source: Item number guide & tables.

Air cap performance data (excerpt)

| Air cap | Air consumption | Inlet pressure | Typical flow | Pattern width (200 mm) |

|---|---|---|---|---|

| TE10 (Trans-Tech) | 255 L/min | 2 bar | 150–200 ml/min | 300 mm |

| TE40 (Trans-Tech) | 355 L/min | 2 bar | 250–400 ml/min | 380 mm |

| HV30 (HVLP) | 450 L/min | ≈1.1 bar | 160–200 ml/min | 315 mm |

| C1 (conventional) | 300 L/min | 3 bar | 150–250 ml/min | 270 mm |

Source: Performance overview (Binks AG-360 Series). :contentReference[oaicite:15]{index=15}

Compatible accessories (selection)

- SPA-417-K Micrometer needle design; SPA-426-K Detent assembly; SPA-167-K End cap fixed needle position; SPA-414-K Control valve; SPA-111-K2 Sealing plug.

- Mounting: AGGS-33 rail, SS-659-CD nut; adapters/rails SPA-173-K/174-K/175-K/176-K.

Why DeVilbiss AG362?

- Very good transmission efficiency (PG6/EPA compliant), fine finish.

- Flexible integration into automation systems (independent air circuits, quick-detach manifold). :contentReference[oaicite:19]{index=19}

- Robust materials & service-friendly design (QuickClean™). :contentReference[oaicite:21]{index=21}

FAQ

Lever vs. screw manifold?

Lever (AG-362L): fastest gun change without loss of position; screw (AG-362S): more compact, multiple mounting options. :contentReference[oaicite:22]{index=22}

Which air caps are available?

Conventional (C1/C2/C3), Trans-Tech (TE10/20/30/40/50), HVLP (HV30, HV40 depending on series). See performance data. :contentReference[oaicite:24]{index=24}

Maximum pressures and temperatures?

Air/liquid 7 bar each; ambient temperature up to 40 °C (nominal).

Material compatibility?

Designed for solvent- and water-based coatings.

Maintenance & downtime?

Simple design, quickly removable manifold for cleaning/servicing & rapid recommissioning. :contentReference[oaicite:27]{index=27}

- Product number: 2180100

- Manufacturer: DeVilbiss

- EAN: 5,02185E+12

- Weight: 1.03 kg

Technical details

| Feature | Value |

|---|---|

| Product range | DeVilbiss AG362 |

| Product type | Automatic compressed air spray gun (low pressure), lever or screw distributor |

| ATEX / Area of application | II 2 G X T6; suitable for Zone 1 / Zone 2 |

| Suitable materials | Solvent-based and water-based materials |

| Air cap options | Conventional, Trans-Tech (high efficiency), HVLP |

| Max. air inlet pressure | 7 bar (≈102 psi) |

| Max. fluid inlet pressure | 7 bar (≈102 psi) |

| Cylinder air pressure (operation) | 4–7 bar (≈58–102 psi) |

| Max. ambient temperature | 40 °C (nominal) |

| Distributor connections | P1 = 1/8" G, P2 = 1/8" G, P3 = 1/8" G |

| Air inlet size | 1/8" G |

| Fluid inlet size | 1/4" G (lever); 1/4" NPS (screw) |

| Dimensions (L × H × W) | Lever manifold: 127 × 97 × 44 mm; screw manifold: 127 × 64 × 89 mm |

| Weight (with manifold) | Lever: approx. 940 g; screw: approx. 850 g |

| Materials – head & fluid lines | Aluminium, Quickclean™ coated |

| Material – Gun body | Chemically nickel-plated brass |

| Material – Air cap | Stainless steel |

| Fluid tip & needle | Stainless steel; needle/tip optionally nitride-coated |

| Seals / O-rings | HDPE, Viton Extreme |

Further manufacturer information

Register