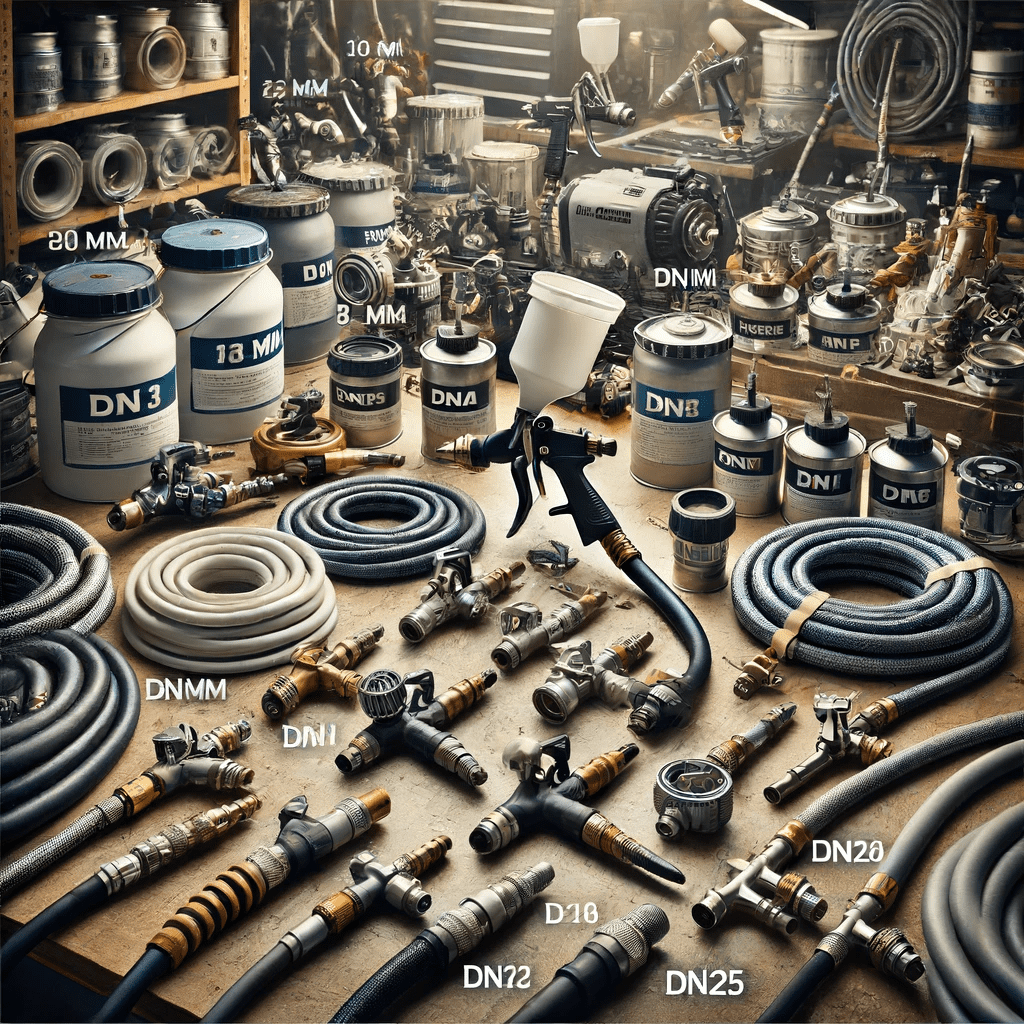

Painting hoses: A guide to changing, diameter and connection for air and material hoses

How often should paint hoses be changed?

Air hoses:

- Intensity of use: Daily use requires more frequent checks and earlier replacement.

- Material quality: High-quality materials such as PU or rubber extend the service life.

- Operating environment: aggressive environments shorten the service life.

Recommended replacement intervals for air hoses:

- Standard operation: Every 12 to 24 months

- Heavy use: Every 6 to 12 months

- Visual inspection: Regularly (at least every 3 months) for cracks and abrasion.

Fluid hoses:

- Type of material: Differences in the chemical composition of the paint material can affect the service life.

- Pressure requirements: Hoses that have to withstand higher pressures (e.g. airless processes) should be checked more frequently.

- Cleaning intervals: Regular cleaning extends the service life of the hoses.

Recommended replacement intervals for material hoses:

- Standard operation: Every 12 to 18 months

- Heavy use: Every 6 to 12 months

- Cleaning and inspection: After every use, especially with heavily pigmented materials.

Finding the right diameter

Air hoses:

- Compatibility: Check the specifications of the spray gun.

- Length of hose: Longer hoses often require a larger diameter.

- Air pressure and air consumption: Make sure that the hose meets the requirements.

Common air hose diameters:

- 8 mm (5/16 inch ): For small to medium-sized spray guns.

- 10 mm (3/8 inch ): universal diameter.

- 13 mm (1/2 inch ): for large-volume applications.

Material hoses:

- Flow rate: The diameter must be large enough to transport the paint material without pressure loss.

- Method: Thicker hoses are often required for airless methods to handle the high pressure.

Common diameters for material hoses:

- DN3 (3 mm internal diameter ): For fine detail work and small quantities of material.

- DN4 (4 mm internal diameter ): For smaller spray guns and fine applications.

- DN6 (6 mm internal diameter ): For medium to large spray guns, universally applicable.

- DN8 (8 mm internal diameter ): for high-viscosity materials and larger surfaces.

- DN10 (10 mm internal diameter ): for high-volume applications and airless systems.

- DN12 to DN25 (12 mm to 25 mm internal diameter ): for industrial applications and systems with high pressure and large quantities of material.

Find the right connection (adapter)

Air hoses:

- Connection types: quick couplings, screw connections, bayonet locks.

- Compatibility: Check the size and type on the hose and the spray gun.

Fluid hoses:

- Pressure requirements: Connections must withstand operating pressure.

- Material compatibility: Choose corrosion-resistant materials for connections.

Tips for selection:

- Material quality: Metal fittings last longer than plastic.

- Safety latches: Prevent accidental disconnection of the hose.

- Seals: Avoid air and material leaks.

Summary

Both air and fluid hoses are crucial to the quality and efficiency of the painting job. Regular maintenance, choosing the right diameter, and appropriate fittings can extend hose life and optimise performance. Whether for air supply or material transport, paying attention to these factors is the key to professional painting results.