The structure of abrasives: an overview

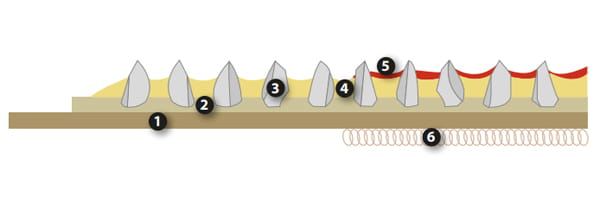

Abrasives are indispensable tools in wood and metalworking. Their structure and the choice of materials used to make them largely determine the efficiency and lifespan of the product. In this article, we will shed light on the most important components of an abrasive and explain their functions and properties. Let's take a look at the six essential components, which are numbered in the attached figure.

1. Backing material

The backing material (1) is the foundation of any abrasive product. It not only serves as the adhesive surface for the abrasive grains, but is also responsible for transferring the forces generated during sanding to the surface being worked on. The larger the abrasive grains, the more force is required, which in turn requires a stronger backing material.

Cloth backings are generally tougher and more stable than paper backings. Depending on the weave, the backing can be either rigid or flexible. Nowadays, however, there are also paper backings that have been specially developed for demanding sanding applications and have a high strength.

2. Backing

The base coat or binder (2) is the first resin layer applied to the backing material. This layer is crucial because it holds the abrasive grains (3) in place. Abrasive manufacturers often use a synthetic resin that offers greater durability and consistent quality compared to natural materials.

3. Abrasive grain

The abrasive grain (3) is the actual abrasive material that is responsible for removing the material. Choosing the right abrasive grain is crucial for the end result. Sharp grains ensure good material removal, while finer grains allow for a smoother finish.

4. size binder

The top layer or top size (4) is applied over the abrasive grains. This second resin layer ensures that the grains remain firmly in place and gives the abrasive a longer lifespan. The amount of resin used plays an important role here: a small amount results in a more aggressive abrasive behaviour, but shortens the lifespan of the product. A larger amount extends the lifespan but reduces the abrasiveness.

5. Stearate coating

The stearate layer (5) is an optional layer that is applied to certain abrasives. It is used to prevent clogging of the abrasive and thus further increase the efficiency and lifespan of the product. This layer is particularly important when working with materials such as wood, as it reduces the clumping of the abrasive grains with wood dust.

6. Fastening system

The mounting system (6) ensures that the abrasive can be securely attached to the grinding machine. There are various systems, which may vary depending on the application and machine. A stable mounting system is important to ensure safe and effective use of the abrasive.

Conclusion

The right combination of these six elements determines the quality and performance of an abrasive. By understanding the individual components and their functions, the selection of the optimal abrasive for specific applications can be made in a targeted manner. This not only increases the efficiency of the work, but also maximises the lifespan of the abrasives.

Interested in high-quality abrasives? Click here to discover our range of Mirka abrasives and find the right product for your needs!