Maximise your production efficiency with electrostatic coating

In today's manufacturing environment, precision and efficiency are key. Electrostatic coating technology offers an innovative solution that not only improves coating quality, but also reduces costs and supports environmental standards.

Find out more about the advantages and safety aspects of this advanced technology and discover why it is used in almost every industry.

Advantages of electrostatic coating:

- Uniform coatings: Electrostatic charging of the paint particles achieves a more even coating that also covers corners and edges that are difficult to access.

- Higher efficiency: Application efficiency improves significantly, resulting in lower coating costs as less paint is wasted.

- Reduced emissions and waste: This technique contributes to cleaner production by minimising the release of solvents and other harmful emissions.

Properties of electrostatic coating:

Faraday cage effect: a phenomenon in which electrostatically charged particles are strongly attracted to earthed surfaces, enabling difficult areas to be effectively coated.

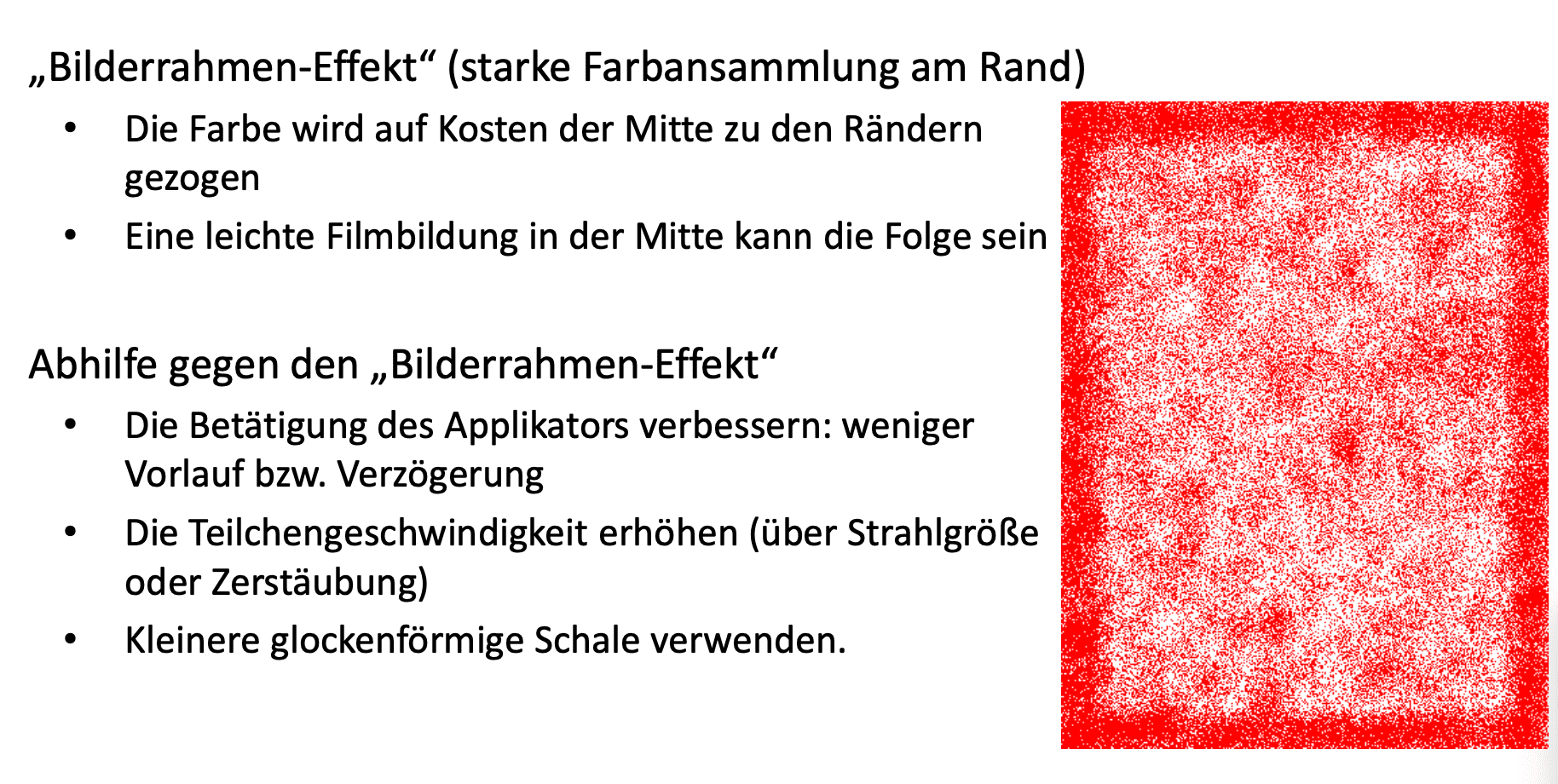

Picture frame effect: Occurs when the edges of an object are coated more heavily than the centre, which can be controlled by technical adjustments.

Material backflow: A challenge that arises when the coating material flows back to the applicator, which can be prevented by proper grounding and equipment maintenance.

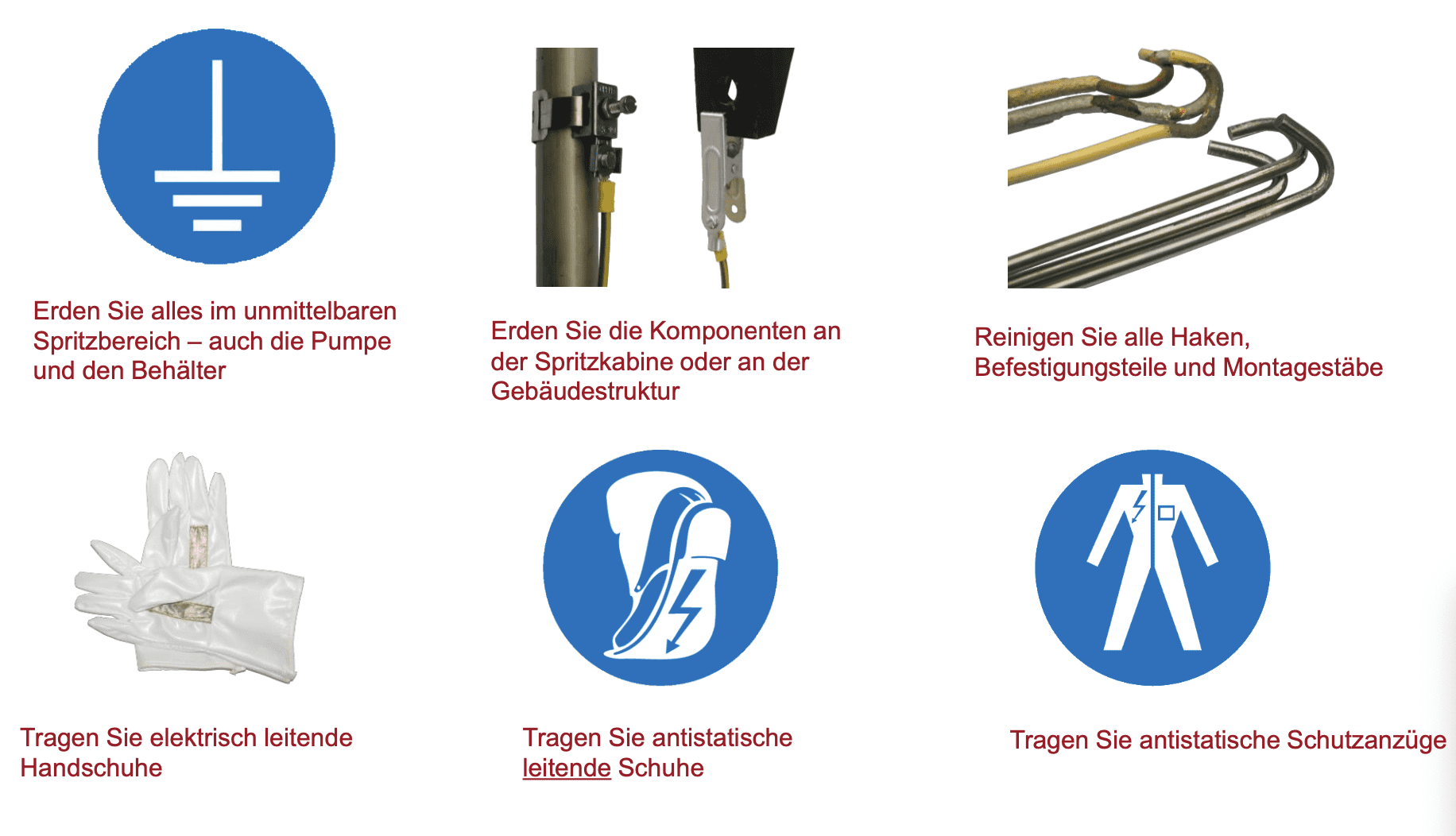

Safety and grounding:

Electrostatic coating requires careful safety measures to avoid accidents and ensure efficient application:

-

Strict

- earthing requirements: All equipment ,

- including applicators and conveyor systems, must be earthed in accordance with EN standards and ATEX guidelines to ensure safety during operation .

- Avoiding electric arcs: Modern applicators are designed so that they do not produce dangerous electric arcs that could ignite an explosive atmosphere .

Conclusion:

electrostatic coating technologies offer an efficient, safe and environmentally friendly solution for modern coating requirements.

From the automotive industry to furniture manufacturing – the areas of application are diverse and offer significant advantages.