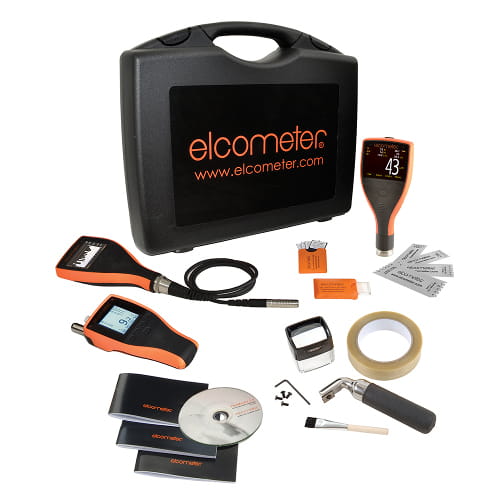

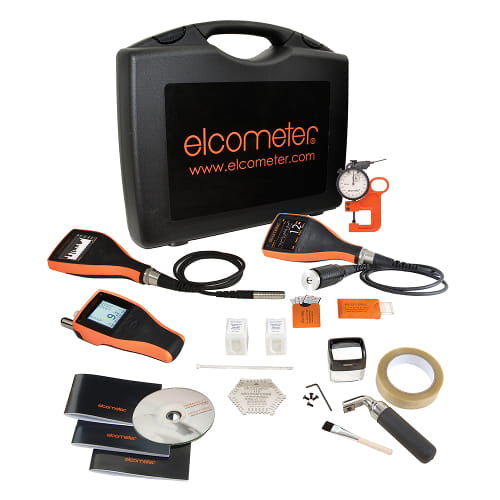

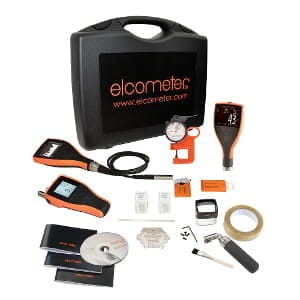

Corrosion protection kits

Compact corrosion protection kits combine all key test instruments for steel and concrete protection

in a robust, portable case.

They contain instruments for dry film thickness measurement (DFT), monitoring of

climate and dew point values (ΔT), determination of the roughness profile as well as instruments for

salt and dust contamination (Bresle test).

The kits are complemented by instruments for holiday detection and adhesion testing.

All components are aligned with the relevant standards such as ISO 12944,

ISO 8501/8502/8503 and ISO 19840 and ensure

standards-compliant quality documentation.

Applications & benefits

The kits are designed for use in steel construction, on bridges, tanks,

in offshore and shipbuilding as well as in concrete repair.

By combining all essential test instruments in one system,

surface preparation, coating monitoring and

final inspection can be carried out efficiently and in accordance with standards.

Users benefit from a higher first-pass yield,

reduced rework and seamless,

audit-proof traceability – from the ΔT check through

DFT testing to release based on salt and dust testing.

Measurement tasks & kit configuration

Dry film thickness (DFT):

Selection of the appropriate gauge and probe

depending on the substrate, e.g. steel,

galvanized steel or reinforcing steel.

Use of calibration foils and zero plates

for standards-compliant calibration and testing according to ISO 19840.

Climate & dew point:

Recording of air temperature, surface temperature,

relative humidity and calculation of ΔT

according to ISO 8502-4.

The results are used to assess coating conditions and

to approve the application environment.

Roughness testing:

Performed using comparison standards

(e.g. Rubert plates) or the

replica method in accordance with ISO 8503.

This precisely determines the surface profile height before coating.

Salt & dust contamination:

Determination of soluble salts using the Bresle test

according to ISO 8502-6/-9 and evaluation of the

dust grade in accordance with ISO 8502-3.

These tests ensure adhesive, clean surfaces

and are part of every quality-assured preparation check.

Holiday detection:

Execution of the holiday test corresponding to the

coating system and test voltage.

In addition, adhesion tests

(e.g. cross-cut or pull-off test)

are used to verify coating quality.

Documentation:

All measurement values are recorded digitally,

documented in accordance with standards and can be exported as

PDF/CSV reports.

Structured data acquisition ensures

auditability and full traceability.

Product ranges & integration

The product range includes standard kits for routine testing as well as

project-specific configured sets with quality assurance software,

data loggers and interfaces for digital reporting.

Together with the user, we define the required scope of testing,

the relevant standards and the measurement point plan.

The test instruments are then fully integrated into existing quality assurance workflows

and documentation systems – fully audit-ready

and traceable.

Benefits at a glance

- Everything in one case – practical selection for steel/concrete

- Standards-compliant – ISO 12944, ISO 8501/8502/8503, ISO 19840, traceably calibratable

- Digital documentation – data export, reports & traceability

- Less rework – clear limit values, consistent approvals

Leading manufacturers – corrosion protection kits

- Elcometer – DFT, Bresle, climate/ΔT, roughness & holiday tests.

- DeFelsko – PosiTector/PosiTest kits for DFT, climate, adhesion & holiday detection.

- BYK-Gardner – gloss/colour & visual inspection for protection systems.

- TQC Sheen – coating inspection cases, cross-cut, wet/dry film thickness.

- Neurtek – complete sets for roughness, adhesion & cleanliness.

- Mahr – roughness/contour measurement for QA before/after coating.

- Rubert – reference plates & comparison standards according to ISO 8503.

- 3M – accessories for surface preparation & cleanliness testing.

- KSJ – portable gloss meters for appearance control.

- Testo – climate/dew point measurement according to ISO 8502-4.

- Datapaq/Fluke – temperature/process loggers (coating curing).

- PCE Instruments – handheld instruments & loggers for field inspection.

- Extech – environmental/electrical measurement for construction sites.

- Rotronic – humidity/temperature for climate kits.

- OMEGA – sensors, probes & data acquisition.

- SATA – test and accessory components.

- Phoenix Instrument – laboratory/test equipment for supporting tests.

- SIS Verlag – standards/guidelines & training materials in the kit.

- beschicht. – QA templates, calibration sets & custom cases.

Go directly to corrosion protection kits –

or to consulting & kit configuration.

Frequently asked questions about corrosion protection kits

Which test instruments belong in a corrosion protection kit?

Typically included are a DFT dry film thickness gauge, climate and dew point measurement (ΔT), roughness profile

(e.g. Rubert/replica), salt and dust contamination (Bresle/ISO 8502), holiday detector,

adhesion (cross-cut/pull-off) as well as lights/magnifiers for visual inspection.

Calibration foils, zero plates and report templates complement the kit.

How do I choose the right corrosion protection kit?

Selection is based on the substrate (steel/galvanizing/concrete), protection system (e.g. ISO 12944 C3–CX),

standards referenced (ISO 8501/8502/8503/19840, ISO 2409), application environment (shipyard, bridge, tank),

documentation requirements (data loggers/interfaces) and required accuracy.

Traceable calibration certificates and a robust case setup are important.

What improves traceability and auditability when using corrosion protection kits?

A defined measurement point plan, calibrated test instruments with certificates, ΔT release before coating,

DFT evaluation according to ISO 19840, salt/dust limit values according to specification, documented roughness profiles

as well as digital reports and photos. Regular test equipment monitoring and user training

ensure consistent results.