The most important spray methods for high-quality painting results

Selecting the right spray method is crucial for perfect painting results. Each method offers specific advantages and influences material consumption, surface quality and efficiency. In this article, we will introduce you to the main atomisation systems, their properties and areas of application, and explain the differences between HVLP and RP.

1. Factors for the right spray method

Various factors play a role in the choice of spraying method. Depending on the size of the object, the quality requirements, the paint system used and the working speed, different systems are optimal. Legal requirements such as the VOC guideline for reducing emissions can also influence the choice of method.

2. The main atomisation systems

Depending on the application and material, there are various atomisation techniques:

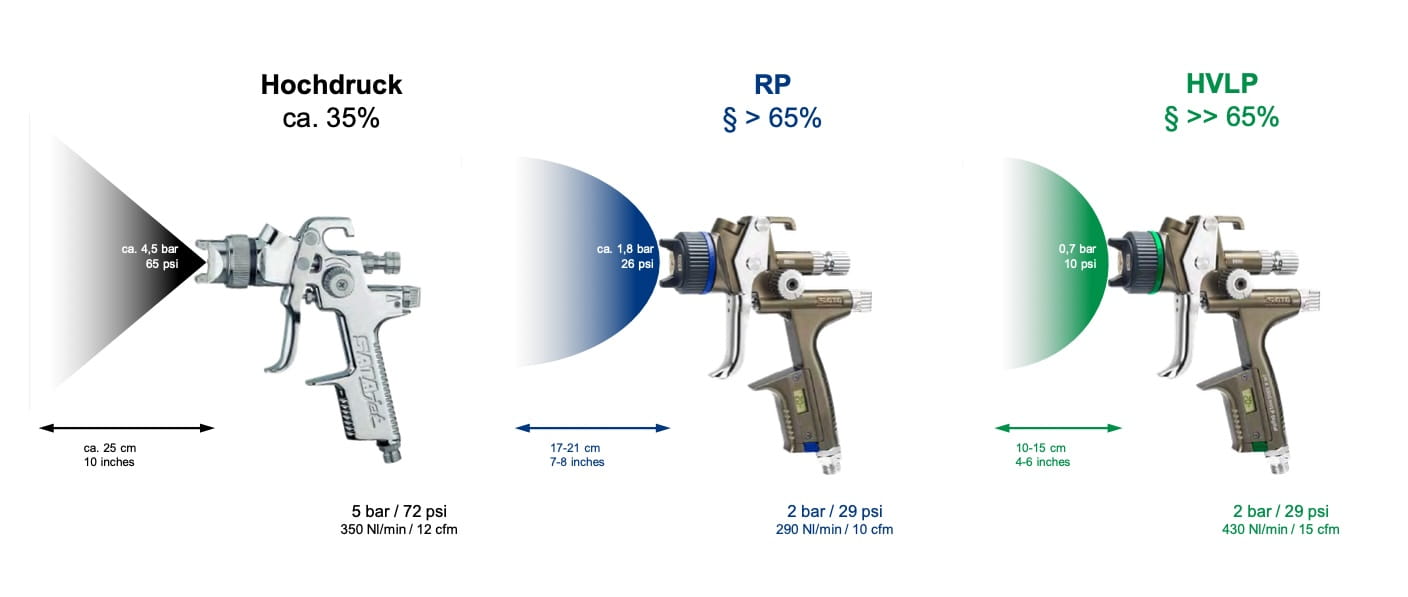

- High-pressure method: In this method, the material is atomised at a nozzle pressure of around 3–10 bar. It is suitable for larger areas as it enables quick application. However, material consumption can increase due to the higher overspray rate.

- Compliance method: with a nozzle pressure of around 2 bar, this method is a cost-effective alternative to the high-pressure method. It offers a better transfer rate and reduces the amount of waste.

- HVLP (High Volume Low Pressure): The HVLP process works with a maximum nozzle pressure of 0.7 bar. The high transfer rate makes it particularly suitable for precise applications, such as those required in vehicle painting. The lower overspray rate is better for the environment and for the budget.

- Airless and air-assisted: In these processes, the material is applied at pressures of up to 300 bar (airless) or 50-150 bar (air-assisted). They are particularly suitable for very large areas and provide high coverage.

3. The importance of the transmission rate

The transfer rate indicates how much of the material actually reaches the surface. The legal requirement is a minimum transfer rate of 65%. In particular, HVLP systems and the reduced pressure (RP) method meet this requirement and at the same time offer a high level of efficiency. The SATAjetX 5500 HVLP achieves particularly high transfer rates, thus reducing overspray, which benefits the environment and health.

4. The influence of the spray fan geometry

The shape and quality of the spray jet are determined by the geometry of the air and paint nozzles, as well as the flow conditions. Well-coordinated jet geometry reduces the error rate and ensures consistent, precise results. This is particularly important for demanding surfaces, where every unevenness becomes visible.

5. Efficient atomisation and low emissions: HVLP technology

HVLP systems were developed to protect the environment and optimise material consumption. They work with low pressure and high volumes, resulting in less paint mist. The high transfer rate ensures that a large proportion of the applied material actually reaches the surface and is not lost as overspray. This makes HVLP technology ideal for applications where precise work and resource conservation are paramount.

The differences between HVLP and RP: two methods for perfect painting results

HVLP (High Volume Low Pressure) and RP (Reduced Pressure) are two spray methods that each offer specific advantages for painting. They have different uses and applications:

HVLP (High Volume Low Pressure)

The HVLP method uses large volumes of air at low pressure. These are the characteristics:

- Nozzle pressure: 0.7 bar (approx. 10 psi) maximum.

- Transfer efficiency: Particularly high as over 65% of the material lands on the surface, reducing overspray.

- Over-spray: Less over-spray, ideal for precise applications such as automotive refinishing.

- Advantages: High material utilisation and better control over paint thickness; saves resources and is environmentally friendly.

- Limitations: Requires a high-powered air supply, so slower over large areas.

Conclusion: HVLP is ideal for precision work and for the environmental protection requirements of the automotive industry.

RP (Reduced Pressure)

The RP process combines the advantages of the high-pressure process with a higher transfer rate and the following properties:

- Nozzle pressure: higher than in HVLP, around 2.0 bar (approx. 29 psi), for faster application over large areas.

- Transfer rate: over 65%, meets regulatory requirements and saves material.

- Paint mist: Less overspray than with high pressure, but more than HVLP; suitable for large areas.

- Advantages: high working speed, even coating, ideal for large-area applications.

- Limitations: Slightly more overspray than with the HVLP method, therefore less suitable for precision work.

Conclusion: RP is the best choice for large-area applications with high efficiency requirements.

Conclusion: the combination of technology and precision

Selecting the appropriate spray method is crucial for the quality and efficiency of your painting work. Each method has its advantages and should be used specifically depending on the application and requirements. Find out more about our range of spray guns and find the right system for your projects.

Discover our spray guns now