Colad UV Putty Transparent – Precise Repairs in the UV Process

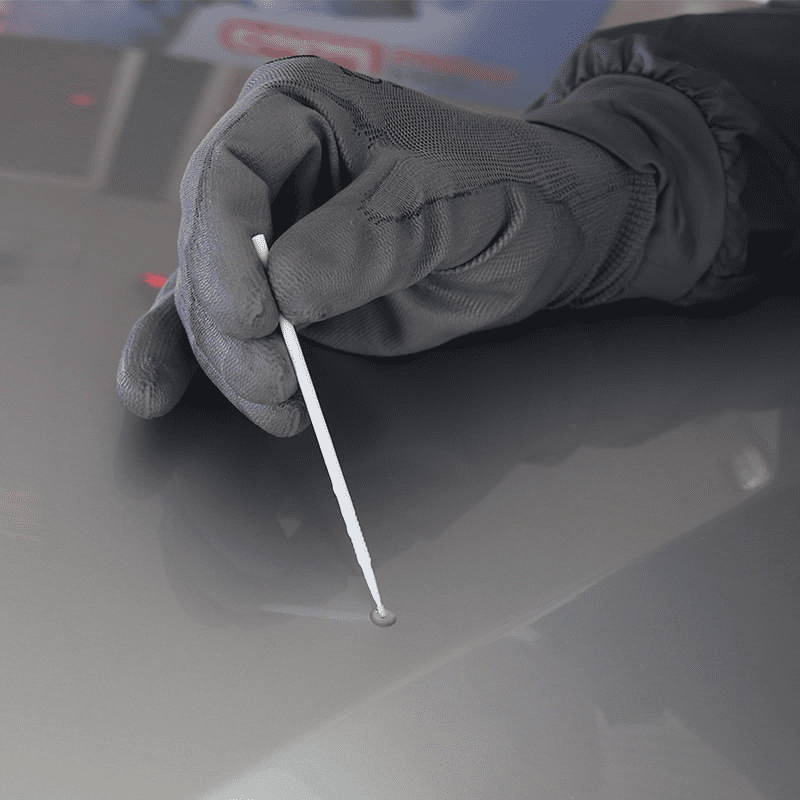

With Colad’s transparent UV Putty, you can repair micro holes, small dents, and especially stone chips quickly and cleanly – ideal for SMART and spot repairs. In combination with the Colad Fast Curing UV Lamp, you drastically shorten waiting times and stay in process flow.

Why Transparent Putty?

The transparent formula allows precise dosing, targeted filling, and easier sanding/polishing without excessive paint build-up. Paired with the UV lamp (high LED intensity and constant output), it ensures a fast, repeatable process with minimal interruptions.

Product Overview & Variants

| Variant | Article No. | Use | Highlights |

|---|---|---|---|

| UV Putty Coarse | 915020 | Small cracks, dents, stone chips | Easy tube dosing |

| UV Putty Fine | 915011 | Finishing tiny surface defects | Ideal for micro holes |

| UV Putty Transparent | 915033 | Precise stone chip repair | 1K, styrene- & solvent-free; ideal for SMART/Spot Repair |

Note: Choose according to damage type. Multiple thin layers can be applied successively.

Order Colad UV Putty Transparent Now

Available at Beschicht.com – integrate it seamlessly into your UV workflow.

Recommended Basic Settings (Reference Values)

- Apply in thin layers; multiple layers can be cured successively.

- Maximum UV-curable layer thickness: approx. 1 mm.

- UV lamp output: ~300 mW/cm² with constant emission.

- Product: 1K, ready-to-use; no hardener; styrene- & solvent-free.

- Curing time depends on thickness & lamp distance – always test first.

All values are approximate; check suitability per application.

Professional Workflow (5–7 Steps)

- Identify damage, sand and round off edges.

- Degrease thoroughly (e.g., with cleaning wipes or sprayer).

- Apply Transparent UV Putty precisely (optionally coarse → fine).

- UV cure in thin layers; repeat if needed.

- Sand flat; use control powder for precision.

- Refill & cure locally until the surface is level.

- Clean and polish – surface is ready for refinishing.

Troubleshooting

- Apply thinner layers; prefer multiple micro passes.

- Perform intermediate sanding using fine grit and control powder.

- Check layer thickness (≤ 1 mm per pass).

- Adjust exposure time and lamp distance for even curing.

- Use finer grit; perform quick UV cures between layers.

- Finish with the Fine variant.

- Always clean and blow off before applying.

- Work in a calm area and cure immediately after application.

Maintenance & Safety

- Always wear UV safety glasses during curing.

- Keep the lamp clean and ventilated.

- Store the putty cool and dark; avoid UV exposure.

- Wear gloves; avoid contact with skin/eyes.

- Replace consumables such as spatulas or touch-up tools regularly.

FAQ – Frequently Asked Questions

What kind of damage is this transparent putty designed for?

For smallest stone chips and micro holes requiring pinpoint filling (SMART/Spot Repair).

Do I need a hardener?

No, it’s a ready-to-use 1K product.

What layer thickness can be UV cured?

Up to approx. 1 mm; apply several thin coats for best results.

Which substrates can I use it on?

Common automotive metals and plastics; always test beforehand.

How soon is it ready for further work?

Immediately sandable and polishable after UV curing (depends on layer and distance).

Conclusion

Colad UV Putty Transparent enables ultra-fast, clean, and pinpoint repairs – perfect for professionals aiming to cut process time while maintaining flawless finish quality. Paired with the Colad UV Lamp, it offers a safe, repeatable process from filling to finishing.